In the realm of auto repair, ensuring the longevity of a vehicle post-collision is paramount. Corrosion protection plays a crucial role in this, especially in areas disturbed during the repair process. Among the various corrosion protection methods, cavity wax stands out as a vital component. But what is cavity wax used for in auto repair, and why is its application so critical?

Cavity wax is specifically designed to protect enclosed areas of a vehicle from rust and corrosion. These areas, often referred to as cavities, include rocker panels, door panels, frame rails, and other structural sections that are prone to trapping moisture and debris. Unlike external panels that are readily accessible and visible, these internal cavities are hidden and harder to treat once corrosion sets in.

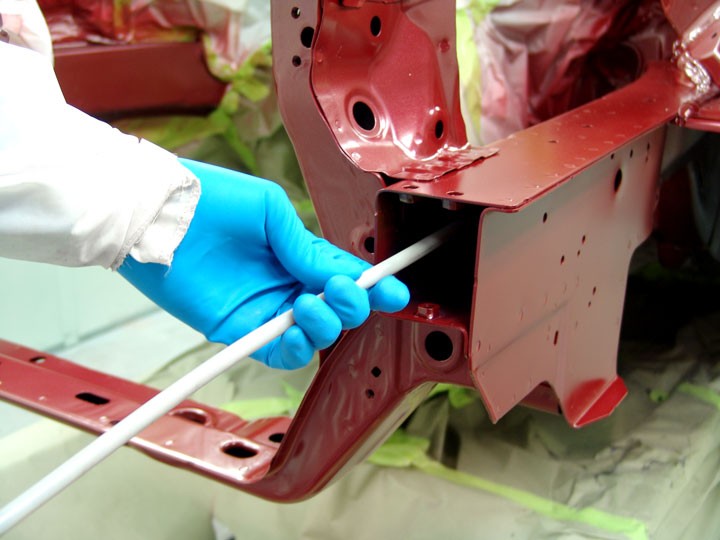

Applying cavity wax for corrosion protection in a vehicle rocker panel during auto body repair to prevent rust and ensure structural integrity.

Applying cavity wax for corrosion protection in a vehicle rocker panel during auto body repair to prevent rust and ensure structural integrity.

The primary function of cavity wax is to create a protective barrier against moisture, salt, and other corrosive elements that can infiltrate these enclosed spaces. By applying cavity wax, technicians can effectively seal these areas, preventing water and contaminants from coming into direct contact with the bare metal. This is particularly crucial after collision repairs, as welding, grinding, and panel replacement can expose bare metal, making these areas highly susceptible to rust formation if left unprotected.

OEMs (Original Equipment Manufacturers) universally recognize the importance of cavity wax and provide specific guidelines for its application. Typically, cavity wax is applied after the vehicle has been repaired, welded, and refinished, but before the installation of trims and moldings. This timing is crucial. Applying cavity wax prematurely, especially before welding, can create significant hazards. As highlighted by a case reported to I-CAR, applying corrosion protection before welding led to propellant fumes igniting and causing an explosion within the rocker panel, resulting in extensive vehicle damage.

Furthermore, understanding when not to apply cavity wax, or when it needs to be removed, is equally important. During certain repair procedures, especially those involving welding or grinding in areas where cavity wax, seam sealers, or foam fillers are present, these materials must be removed to prevent fire hazards. Auto body repair manuals provide detailed locations of these materials, guiding technicians on where removal is necessary before commencing work. Accessing these cavities for wax application might sometimes require further disassembly, but drilling additional access holes is generally discouraged.

In conclusion, cavity wax is an indispensable corrosion protection product in auto repair, specifically used to safeguard enclosed cavities from rust and corrosion. Its correct application, at the right stage of the repair process and in accordance with OEM guidelines, is essential for ensuring the longevity and structural integrity of the repaired vehicle, while also preventing potential safety hazards. Always consulting the vehicle’s body repair manual is paramount before undertaking any corrosion protection application.