Wheels are a crucial part of any vehicle, influencing both its performance and aesthetics. For car enthusiasts, the right set of wheels can dramatically enhance a vehicle’s look, completing hours of meticulous modifications. However, when it comes to purchasing wheels, the allure of lower prices can sometimes overshadow the importance of quality. This is where the concept of “reps,” or replica wheels, comes into play.

In the automotive world, using replica wheels is akin to wearing imitation designer goods. They might look the part and complement your car’s style, but beneath the surface, there are significant differences. While genuine, high-quality wheels are the result of extensive research and development, ensuring safety and reliability, replica wheels often cut corners to offer a cheaper alternative.

Understanding Alloy Wheel Manufacturing

To understand the difference, it’s helpful to know how alloy wheels are made. Alloy wheels, commonly used in modern vehicles, are produced by casting a mixture of molten aluminum and magnesium into a mold. This process, which became popular in the 20th century, offered lighter and almost as durable alternatives to steel wheels.

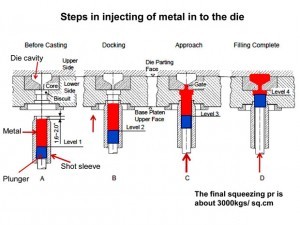

Today, three primary casting methods are employed: gravity casting, low-pressure casting, and high-pressure casting. Gravity casting is the most economical, relying on gravity to fill the mold. However, this method can lead to air pockets and impurities, resulting in a weaker wheel. Low-pressure casting uses positive pressure to force the molten alloy into the mold, creating a denser and stronger wheel compared to gravity casting. High-pressure casting is similar to low-pressure casting but utilizes even greater pressure for enhanced density and strength.

Forged wheels represent another manufacturing method, distinct from casting. Forged wheels are machined from a solid billet of aluminum, eliminating air pockets and imperfections, resulting in the strongest type of alloy wheel. Each casting method, along with forging, dictates the wheel’s quality, strength, and consequently, its price.

The Price Discrepancy: Real vs. Reps

The price difference between genuine and replica wheels is stark. A quick online search for genuine BBS RS Series wheels reveals prices ranging from $1,500 to $2,100 per set, depending on size. In contrast, replica versions, such as STR RS series wheels, can be found for around $166 per wheel, totaling approximately $700 for a set. This significant price gap reflects the differences in manufacturing processes, materials, and quality control.

Replica Wheels: When Are They Acceptable?

Replica wheels shouldn’t be dismissed entirely. Their suitability depends heavily on their intended use and manufacturing quality. For everyday driving or purely cosmetic enhancements, replica wheels can be a viable, budget-friendly option. If you’ve damaged a stock wheel on your daily commuter and need a replacement, many companies offer replica wheels that closely resemble OEM designs at a lower cost. Similarly, for show cars or vehicles primarily used for static display, replica wheels can provide the desired look without the high cost of genuine performance wheels. In these scenarios, gravity-cast or low-pressure cast replica wheels might suffice.

However, for performance applications, such as track days or drag racing, or for high-horsepower vehicles, the use of cheap, poorly manufactured replica wheels becomes a significant safety concern. These wheels often lack the rigorous testing and quality control of reputable brands. Under high stress from intense cornering, acceleration, or braking, substandard replica wheels can suffer catastrophic failures, such as spoke fractures or lip breaks, potentially leading to loss of vehicle control and accidents.

Investing in Quality for Peace of Mind

While high-pressure cast wheels and especially forged wheels can withstand track use, the crucial factor is understanding the intended application and prioritizing safety. Choosing genuine wheels from reputable manufacturers is always the safer and more reliable approach. Although the upfront cost is higher, the investment in quality wheels ensures greater durability, performance, and most importantly, safety. While budget constraints are a reality, compromising on wheel quality can lead to significant risks, making the slightly higher price of genuine wheels a worthwhile investment for peace of mind and safety on the road.