Experiencing a flat tyre can be an unwelcome disruption to your journey. While the urge to quickly get back on the road is understandable, it’s crucial to understand that not all tyre repairs are created equal. Knowing how to repair puncture car tyre correctly is paramount for your safety and the longevity of your tyre. This guide will walk you through the industry-recommended procedures for a safe and durable tyre repair, highlighting why temporary fixes often fall short and could put you at risk.

Why Temporary Tyre Repairs Like Plugs and Strings Aren’t Enough

Many motorists resort to using tyre plugs or string repairs as a quick fix for punctures, especially in roadside emergencies. These methods involve inserting a self-vulcanizing plug or string into the puncture from the outside of the tyre, without removing it from the wheel. While these repairs might seem effective initially by stopping air leakage, they are fundamentally temporary and can lead to serious problems down the line.

The primary issue with plug and string repairs is that they do not create a complete and permanent seal of the tyre injury. Although they may hold air effectively, they fail to seal the inner layers of the tyre from moisture and contaminants. This penetration can lead to corrosion of the steel belts within the tyre structure and potentially cause a dangerous tyre blowout while driving at speed. Relying solely on these methods is a gamble with your safety, and understanding how to repair puncture car tyre properly is the safer alternative.

The Problem with Patch-Only Tyre Repairs

Another common misconception is that applying a patch to the inner liner of the tyre is sufficient for a proper repair. Similar to plug-only repairs, a patch applied in isolation does address the immediate problem of air loss. A patch alone, when properly applied, will indeed prevent air from escaping through the puncture.

However, the critical flaw with patch-only repairs lies in their inability to seal the puncture channel itself. Just like with plugs and strings, moisture, dirt, and debris can still enter the tyre through the external puncture wound, reaching the tyre’s internal structure. This can lead to progressive damage to the tyre’s plies and belts over time, weakening its integrity and increasing the risk of failure. A patch alone doesn’t address the root cause of the problem – sealing the entire injury channel – which is a crucial aspect of how to repair puncture car tyre safely.

The Industry-Recommended Tyre Repair Process: R.E.P.A.I.R.

For a tyre repair to be considered safe and permanent, industry guidelines mandate a combination patch and plug repair. This method addresses both sealing the puncture channel and reinforcing the inner liner. The process, often remembered by the acronym R.E.P.A.I.R., involves several critical steps performed from the inside of the tyre after removing it from the wheel.

-

Remove: The first and essential step in how to repair puncture car tyre properly is to remove the tyre from the wheel assembly. This allows for a thorough inspection of both the internal and external damage to the tyre, which is impossible to do with the tyre mounted.

-

Evaluate: Once the tyre is demounted, a careful evaluation of the puncture is necessary. This includes determining the size, direction, and angle of the injury. It’s also crucial to check for any internal damage to the tyre’s cords, belts, or sidewall. This evaluation determines if the tyre is even suitable for repair.

-

Prepare: If the tyre is deemed repairable, the preparation phase begins. This involves cleaning and preparing both the puncture channel and the inner liner for the repair materials. The puncture channel is typically drilled out using a carbide cutter to remove damaged cords and create a clean path for the plug portion of the repair. The inner liner around the puncture area is then buffed to create a slightly rough surface, which enhances adhesion for the repair patch.

-

Apply: Vulcanizing cement is applied to the prepared puncture channel and the buffed area on the inner liner. This chemical solution is crucial for creating a strong bond between the tyre rubber and the repair unit. The cement needs to be allowed to air dry for 5-10 minutes to become tacky.

-

Install: The next step in how to repair puncture car tyre is installing a combination repair unit. This unit typically consists of a plug portion that fills the prepared puncture channel from the inside out and a patch portion that bonds to the buffed inner liner. The plug is pulled through the puncture from the inside, and the patch is firmly pressed onto the inner liner. A tyre stitcher (a small rolling tool) is used to thoroughly stitch the patch to the inner liner, ensuring complete adhesion and removing any trapped air bubbles. Excess plug material protruding from the tyre’s tread is trimmed to about ¼ inch.

-

Return to Service: The final step in how to repair puncture car tyre is getting the tyre back into service safely. After the repair is installed, a rubber sealant may be applied around the edge of the patch on the inner liner for added protection. The tyre is then remounted onto the wheel, inflated to the correct pressure, balanced, and reinstalled on the vehicle.

Is Your Punctured Tyre Repairable? Key Considerations

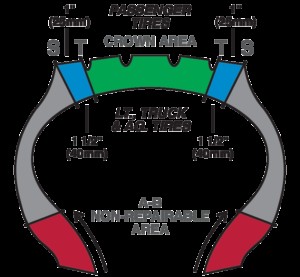

the repairable are of most tires is restricted to the crown

the repairable are of most tires is restricted to the crown

Not every punctured tyre can or should be repaired. Several factors determine whether a repair is safe and feasible. When considering how to repair puncture car tyre, assess these critical aspects:

-

Location of the Injury: For passenger car tyres, repairs are only permissible within the crown area – the central tread area of the tyre. Damage to the shoulder (the area between the crown and sidewall) or the sidewall itself is generally not repairable due to the flexing and stress these areas endure.

-

Size of the Puncture: There are limitations on the size of the puncture that can be safely repaired. For most fabric-ply passenger and light truck tyres, the maximum allowable puncture size for repair is ¼ inch (6mm). For steel-belted light truck, medium, and heavy-duty truck tyres, this limit is slightly larger at 3/8 inch (10mm). Punctures exceeding these sizes often indicate more extensive internal damage.

-

Overall Tyre Condition: The general condition of the tyre plays a significant role in repairability. Tyres with excessive wear, pre-existing casing separations, impact damage, run-flat damage, or previous improper repairs may not be safe to repair. For a more detailed understanding of repairable versus non-repairable tyre conditions, resources like “Can Your Tire Be Repaired?” offer valuable insights.

Conclusion

Dealing with a flat or leaky tyre is an inevitable part of vehicle ownership. However, when it comes to how to repair puncture car tyre, prioritizing safety and longevity over quick fixes is paramount. Taking shortcuts with temporary repairs can compromise your safety and potentially lead to tyre failure. Always aim for a proper patch/plug combination repair performed by a qualified technician or, if you are experienced, following the correct procedure diligently. Investing the time and effort into proper tyre repair ensures your safety and maximizes the lifespan of your tyres.