Car body repair solder is a crucial technique for restoring damaged vehicle panels. This guide dives deep into the intricacies of soldering in auto body repair, covering everything from the basics to advanced techniques, empowering you to achieve professional-grade results. We’ll explore the types of solder, essential tools, and step-by-step procedures for a seamless repair.

Understanding Car Body Repair Solder: Why, When, and How

Soldering offers a unique approach to repairing car bodies, particularly for smaller dents, holes, and rust damage. Unlike welding, which melts the base metal, soldering joins metals by melting a filler metal (solder) at a lower temperature. This makes it ideal for delicate repairs and areas susceptible to heat distortion. Soldering provides a strong, durable bond, creating a smooth, even surface that’s perfect for preparing the area for body filler. Is it right for every repair? No. But knowing when and how to use it can be a game-changer in your auto body work.

Have you ever considered using solder for your car body repairs? It’s a more delicate approach compared to traditional welding. can you use solder for car body repairs provides a helpful overview of its suitability for different types of repairs.

Choosing the right steel for repairs is essential. car body repair steel offers valuable information about the different types of steel used in car body construction.

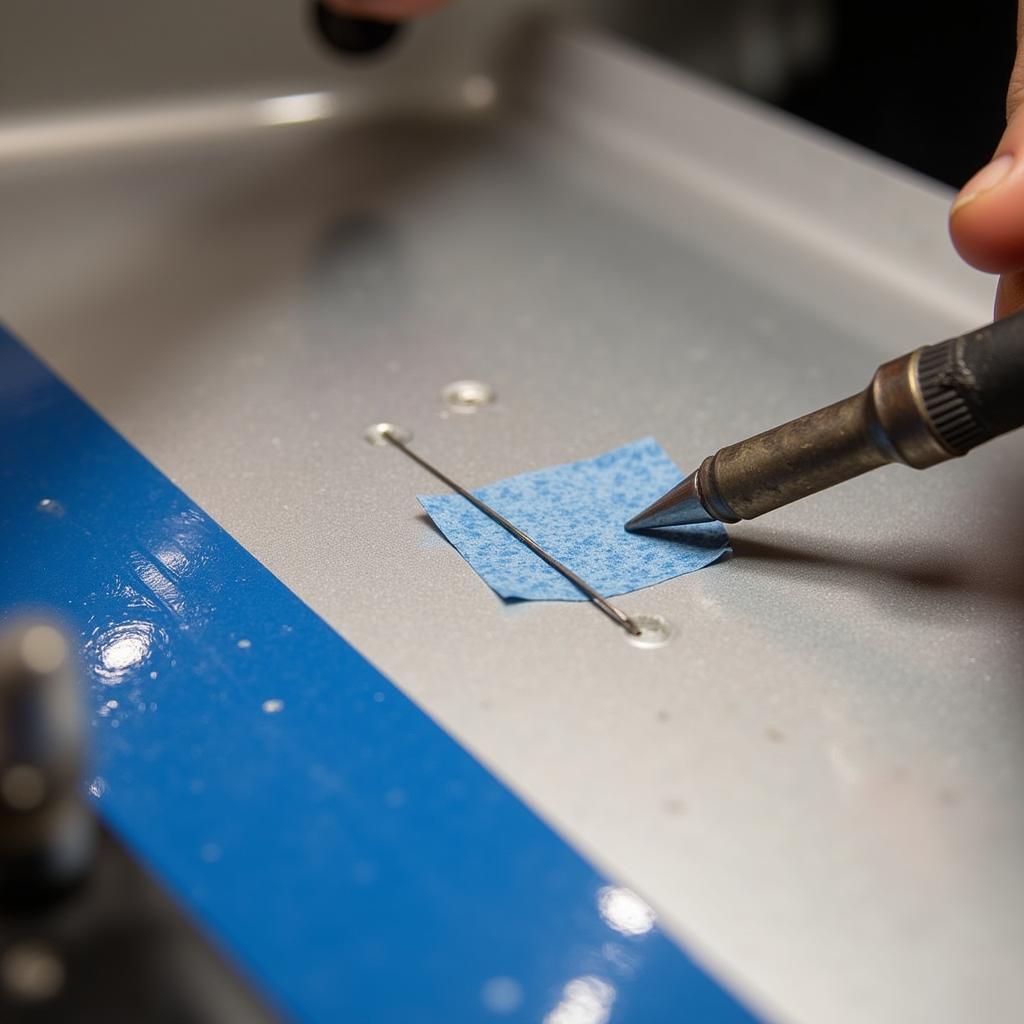

Car body repair soldering process in action

Car body repair soldering process in action

Essential Tools and Materials for Car Body Soldering

Before embarking on any car body solder repair, gather the necessary tools and materials. This includes a soldering iron with adjustable temperature control, various solder types (lead-free and leaded options available), flux specifically designed for automotive applications, sandpaper for preparing the surface, safety glasses, gloves, and a heat-resistant work surface. Investing in high-quality tools and materials ensures a successful and long-lasting repair.

Choosing the Right Solder for Your Repair

Selecting the appropriate solder is crucial for achieving optimal results. Lead-free solders are environmentally friendly and generally preferred, but leaded solders may offer better flow and strength in some situations. Consider the specific needs of your repair when choosing the solder type. For example, a higher melting point solder is necessary for areas exposed to high temperatures.

Step-by-Step Guide to Car Body Soldering

- Prepare the Surface: Thoroughly clean the damaged area with sandpaper to remove any rust, paint, or contaminants. A clean surface ensures proper solder adhesion.

- Apply Flux: Apply flux to the cleaned area and the solder wire. Flux helps to clean the metal further and promotes better solder flow.

- Heat the Metal: Using the soldering iron, heat the area to be repaired. Avoid overheating, which can damage the surrounding metal.

- Apply the Solder: Touch the solder wire to the heated area, allowing it to flow smoothly and fill the damaged section. Don’t directly apply the soldering iron to the solder wire; let the heat from the metal melt the solder.

- Smooth and Finish: Once the solder has cooled, use sandpaper or a file to smooth and shape the repaired area. This prepares the surface for body filler and paint.

If you’re looking to repair a radiator, you might be wondering about using body filler. Check out car body filler for repairing radiator for insights into this specific application.

Safety Precautions for Car Body Soldering

Always prioritize safety when performing any car body repair, including soldering. Wear appropriate safety glasses and gloves to protect yourself from heat and fumes. Work in a well-ventilated area to avoid inhaling solder fumes, especially when using leaded solder. Keep a fire extinguisher nearby and be aware of the potential fire hazards associated with working with heat.

Common Mistakes to Avoid When Soldering

- Overheating: Overheating can warp the metal and create further damage. Use an adjustable temperature soldering iron and monitor the heat carefully.

- Insufficient Cleaning: A dirty surface will prevent proper solder adhesion, leading to a weak repair.

- Using the Wrong Solder: Using the incorrect type of solder can result in a poor bond or unwanted reactions with the base metal.

Conclusion

Car body repair solder offers a valuable technique for restoring damaged vehicle panels with precision and control. By understanding the process, choosing the right materials, and following the proper steps, you can achieve professional-quality repairs and extend the life of your vehicle’s body. Remember to always prioritize safety and take the necessary precautions to ensure a safe and successful repair. Now, you have the knowledge to confidently tackle your next car body repair project with solder.

FAQs

- What is the difference between soldering and welding in car body repair?

- Can I use a regular soldering iron for car body repair?

- What type of flux should I use for car body soldering?

- How do I prepare the surface for soldering?

- Is car body repair solder strong enough for structural repairs?

- How do I prevent warping when soldering car body panels?

- What are the safety precautions for car body soldering?

Need assistance with your car repair? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected]. Our 24/7 customer support team is ready to help.