Understanding car body metal seal repair thickness is crucial for ensuring a proper and long-lasting repair. Whether you’re a DIY enthusiast or a professional technician, getting the right sealant thickness is essential for preventing leaks, corrosion, and structural weaknesses. This article will delve into the intricacies of car body metal seal repair thickness, providing you with the knowledge and insights you need to achieve professional-quality results.

Factors Influencing Car Body Metal Seal Repair Thickness

Several factors determine the ideal car body metal seal repair thickness. These include the type of sealant used, the size and depth of the repair area, the material being sealed (e.g., steel, aluminum), and the environmental conditions the vehicle will be exposed to. Using too little sealant can lead to leaks and corrosion, while using too much can create a messy finish and potentially interfere with other components.

Choosing the Right Sealant for Your Car Body Repair

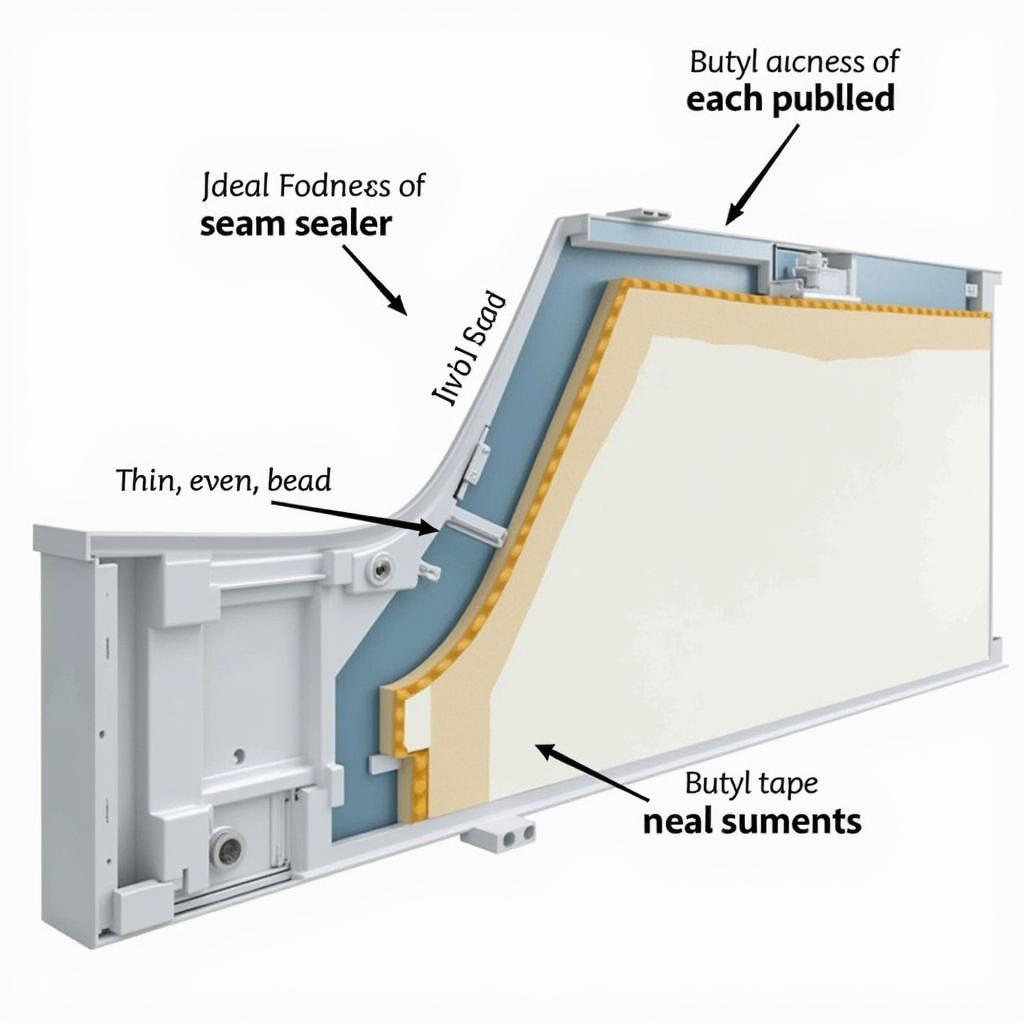

The type of sealant you choose plays a significant role in determining the appropriate thickness. Common sealants used in car body repair include seam sealers, butyl tape, and urethane adhesives. Each type has unique properties and recommended application thicknesses. For example, seam sealers are typically applied in thinner layers than butyl tape, which is used for filling larger gaps and providing a watertight seal.

Seam Sealers: A Thin Layer for a Strong Bond

Seam sealers are often used to replicate the factory seals found on car bodies. They are applied in a thin, consistent bead along seams and joints to prevent water intrusion and corrosion. The ideal thickness for seam sealer application is typically between 2-4 mm. Over-applying seam sealer can result in a messy finish and may require additional sanding or trimming.

Butyl Tape: Filling Gaps and Creating a Watertight Seal

Butyl tape is a thicker, more pliable sealant used to fill larger gaps and provide a robust, watertight seal. Its thickness can vary depending on the specific product, but it’s generally applied in a thickness of 3-6 mm or more, depending on the gap being filled. Butyl tape is excellent for sealing areas around windows, windshields, and other components where a thicker, more flexible seal is needed.

Considering Environmental Factors

The environment your vehicle is exposed to can also influence the required car body metal seal repair thickness. If the vehicle is frequently exposed to harsh weather conditions, such as extreme temperatures or high humidity, a thicker sealant layer may be necessary to provide adequate protection.

Achieving the Correct Car Body Metal Seal Repair Thickness

Achieving the correct car body metal seal repair thickness requires careful preparation and application. Before applying any sealant, thoroughly clean and prepare the surface to ensure proper adhesion. Follow the manufacturer’s instructions for the specific sealant being used, as they will provide guidance on the recommended thickness and application techniques.

Tips for Applying Car Body Sealant

- Use a caulking gun or applicator designed for the specific sealant to ensure a consistent bead.

- Apply the sealant in a continuous motion to avoid gaps or air pockets.

- Use a smoothing tool to create a neat, even finish and remove excess sealant.

- Allow the sealant to cure completely before exposing the vehicle to moisture or other environmental factors.

“Ensuring the correct sealant thickness is paramount for a successful car body repair. It’s not just about preventing leaks; it’s about preserving the structural integrity of the vehicle and preventing future corrosion issues,” says John Miller, a veteran auto body repair specialist with over 25 years of experience.

Common Mistakes to Avoid

- Applying sealant to a dirty or unprepared surface.

- Using the wrong type of sealant for the application.

- Applying sealant in too thick or too thin of a layer.

- Failing to allow the sealant to cure properly.

“Remember, the right sealant thickness is like Goldilocks and the three bears – not too thick, not too thin, but just right,” adds Maria Sanchez, a certified automotive technician and instructor.

Conclusion

Car body metal seal repair thickness is a critical factor in ensuring a durable and effective repair. By understanding the factors that influence sealant thickness and following the proper application techniques, you can achieve professional-quality results and protect your vehicle from leaks, corrosion, and structural weaknesses. Choosing the correct sealant and applying it with the right thickness is essential for a long-lasting repair.

FAQ

- What happens if the car body metal seal is too thin?

- What happens if the car body metal seal is too thick?

- What are the different types of car body sealants available?

- How do I prepare the surface before applying car body sealant?

- How long does it take for car body sealant to cure?

- What tools do I need for car body metal seal repair?

- How can I tell if my car body metal seal needs repair?

Common Car Body Metal Seal Repair Scenarios

- Repairing rust holes or damaged areas on the body panels

- Sealing seams and joints after welding or bodywork

- Replacing or resealing windshields and windows

- Repairing leaks around doors, trunk, or hood

Related Articles

- Understanding Car Body Rust Repair

- Choosing the Right Automotive Sealants

- DIY Car Body Repair Tips

Need help with your car body repair? Contact us via WhatsApp: +1(641)206-8880, Email: [email protected]. We have a 24/7 customer support team ready to assist you.