Aluminium car body repairs are becoming increasingly common as more manufacturers turn to this lightweight metal for its fuel efficiency and performance benefits. While aluminium offers numerous advantages, it also presents unique challenges when it comes to repairs. This comprehensive guide will delve into the intricacies of aluminium car body repairs, equipping you with the knowledge to make informed decisions for your vehicle.

Understanding Aluminium in Car Manufacturing

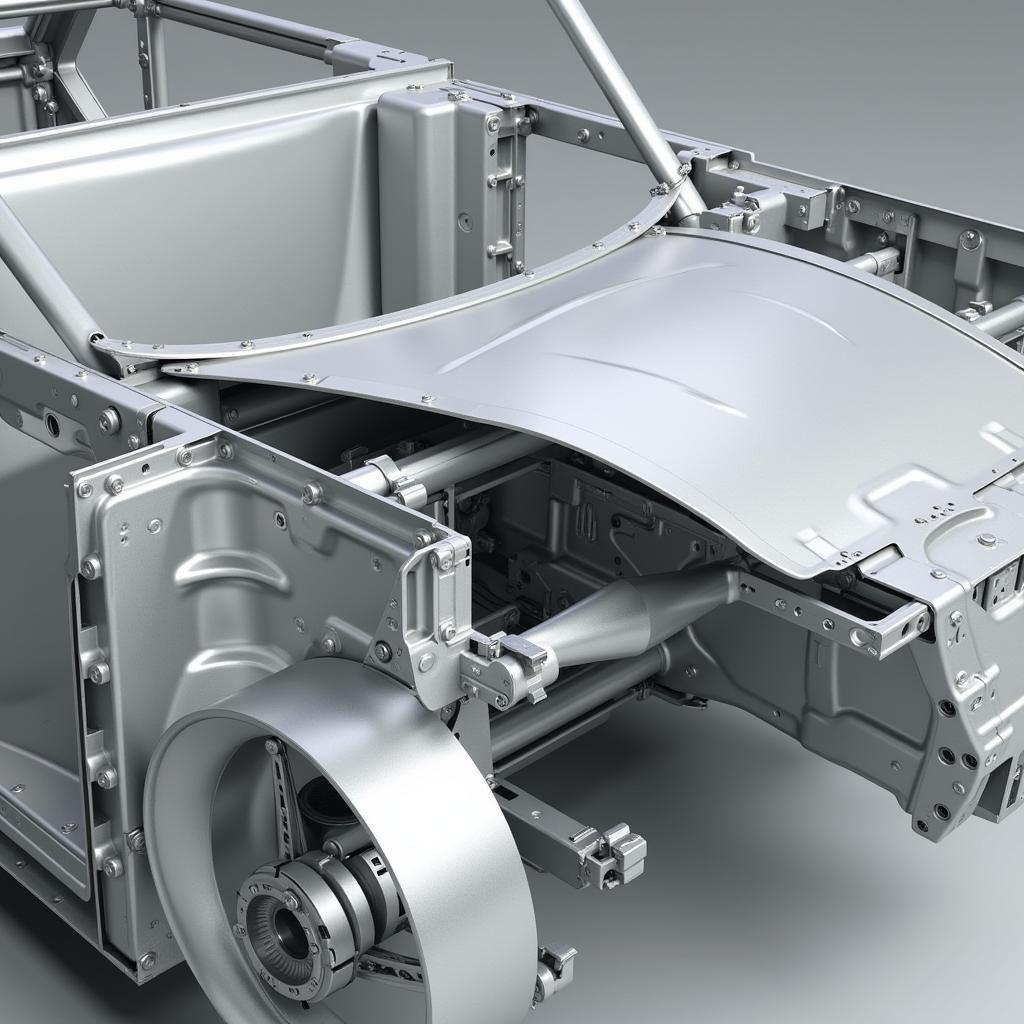

The automotive industry’s shift towards aluminium is driven by its impressive strength-to-weight ratio. Aluminium is significantly lighter than steel, which translates to improved fuel economy and reduced emissions. Additionally, its inherent corrosion resistance contributes to vehicle longevity. However, the same properties that make aluminium desirable also require specialized techniques for repairs.

The Challenges of Aluminium Car Body Repairs

Aluminium’s lower melting point and higher thermal conductivity compared to steel necessitate specialized welding equipment and techniques. Improper welding can lead to warping, weakening the structural integrity of the car body. Moreover, aluminium’s tendency to oxidize rapidly requires meticulous surface preparation to ensure proper adhesion of fillers and paints.

Finding Qualified Professionals for Aluminium Car Body Repairs

Not all auto body shops are equipped to handle aluminium car body repairs. Seek out reputable facilities with certified technicians specializing in aluminium welding and repair. These experts undergo rigorous training to master the intricacies of working with this metal. Inquire about their experience, certifications, and the equipment they utilize to ensure your vehicle is in capable hands. For residents of South Liverpool, consider the reputable services available at car body repairs south liverpool.

The Aluminium Car Body Repair Process

1. Damage Assessment and Repair Planning

A thorough assessment of the damage is crucial to determine the extent of repairs required. Experienced technicians use specialized tools to measure the severity of dents, creases, and structural damage. This evaluation informs the repair plan, ensuring all affected areas are addressed effectively.

2. Straightening and Panel Replacement

Minor dents and dings can often be repaired using specialized tools designed for aluminium. However, significant damage might necessitate panel replacement. In such cases, technicians utilize factory-approved parts and techniques to ensure a seamless and structurally sound repair.

3. Welding and Bonding

Welding aluminium requires specialized equipment and expertise to prevent warping and ensure strong, durable joints. Modern welding techniques like MIG (Metal Inert Gas) welding create clean, precise welds. In some instances, adhesive bonding might be employed as a complementary technique, further enhancing the strength and integrity of the repair.

4. Surface Preparation and Finishing

Before painting, the repaired area undergoes meticulous surface preparation. This involves sanding to remove imperfections and applying specialized primers designed for aluminium. The primer promotes adhesion and prevents corrosion, ensuring a long-lasting and visually appealing finish.

5. Painting and Curing

The final step involves applying high-quality automotive paint that matches the existing finish of your vehicle. Modern paint systems are specifically formulated to adhere well to aluminium and provide excellent durability and UV resistance. The paint is then cured using specialized equipment to ensure proper hardening and a flawless appearance.

Cost Considerations for Aluminium Car Body Repairs

Aluminium car body repairs tend to be more expensive than steel repairs due to the specialized equipment, materials, and expertise required. Factors influencing the cost include the extent of damage, the need for panel replacement, and the complexity of the repair. It’s essential to obtain detailed quotes from reputable shops specializing in aluminium repairs to compare prices and services offered. If you’re in Liverpool, you can find competitive car body repair liverpool prices from trusted professionals.

Maintaining Your Aluminium Car Body

Proper maintenance can significantly prolong the lifespan of your aluminium car body and prevent costly repairs. Regularly wash and wax your vehicle to protect the paint and prevent corrosion. Address any chips or scratches promptly to prevent them from spreading and compromising the underlying metal. Consider applying paint protection film to vulnerable areas prone to stone chips and road debris.

Conclusion

Aluminium car body repairs demand a high level of expertise and specialized techniques. By understanding the intricacies involved, you can make informed decisions regarding the repair of your vehicle. Seeking out qualified professionals equipped with the necessary skills and equipment ensures a safe, durable, and aesthetically pleasing outcome. For those interested in exploring career opportunities in this field, there are various car body repair jobs available that offer rewarding challenges and continuous learning opportunities.