Adhesive metal car body repair is rapidly gaining popularity in the automotive industry as a reliable and efficient alternative to traditional welding techniques. This innovative method utilizes high-strength adhesives to bond metal panels, offering numerous advantages over conventional repair procedures.

Adhesive Metal Car Body Repair Process

Adhesive Metal Car Body Repair Process

Understanding Adhesive Metal Car Body Repair

Unlike welding, which involves melting metal to create a joint, adhesive bonding relies on specialized adhesives that chemically cure and harden to form an incredibly strong bond between metal surfaces. This method eliminates the need for heat, making it ideal for repairing heat-sensitive areas of a vehicle without compromising the structural integrity of the metal.

Advantages of Adhesive Bonding in Car Repair

The automotive industry is increasingly embracing adhesive metal car body repair due to its numerous advantages:

- Enhanced Durability: Adhesive bonds offer exceptional strength and fatigue resistance, ensuring long-lasting repairs that can withstand vibrations and stress.

- Improved Aesthetics: Adhesive bonding eliminates weld lines and distortion, resulting in a smoother, more aesthetically pleasing finish.

- Corrosion Resistance: Adhesives act as a barrier against moisture and contaminants, effectively preventing rust and corrosion in the repaired area.

- Weight Reduction: Adhesives are significantly lighter than welding materials, contributing to improved fuel efficiency and vehicle performance.

- Versatility: Adhesive bonding is compatible with various metals, including aluminum, steel, and high-strength alloys, expanding its applications in modern vehicle construction.

The Adhesive Metal Car Body Repair Process

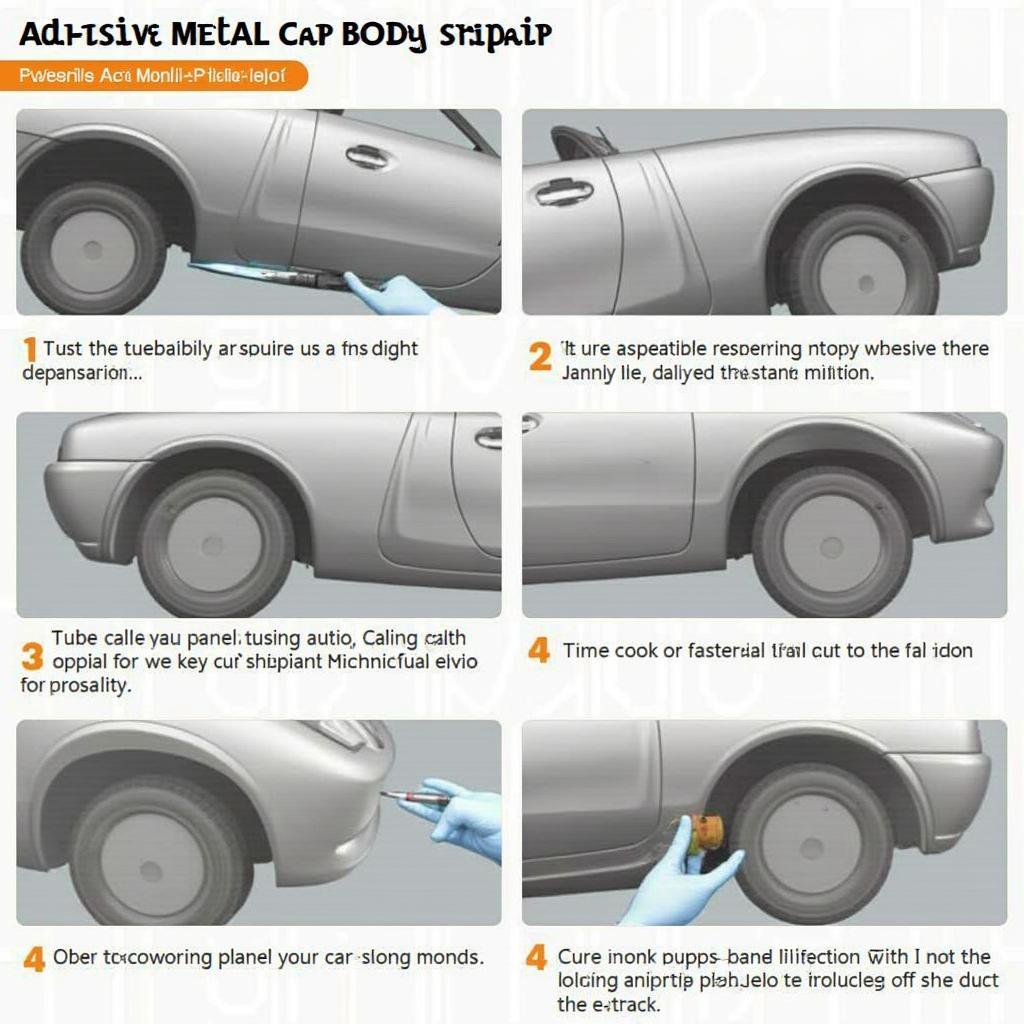

A typical adhesive metal car body repair process involves the following steps:

- Surface Preparation: The damaged area is thoroughly cleaned and prepped to ensure proper adhesion. This includes removing rust, paint, and contaminants.

- Adhesive Application: A specialized automotive adhesive is applied to the prepared surfaces, following the manufacturer’s instructions.

- Panel Bonding: The metal panels are precisely aligned and joined together, applying firm pressure to ensure optimal contact and adhesive distribution.

- Curing: The adhesive is allowed to cure and harden, typically at room temperature or with the assistance of heat lamps, depending on the specific adhesive used.

Choosing the Right Adhesive for Car Body Repair

Selecting the appropriate adhesive is crucial for a successful repair. Factors to consider include:

- Type of Metal: Different adhesives are formulated for specific metal types, ensuring optimal adhesion and compatibility.

- Bonding Strength: Adhesives are available in varying strengths to meet the demands of different repair scenarios.

- Curing Time: The curing time can vary significantly between adhesives, impacting the overall repair time.

Conclusion

Adhesive metal car body repair represents a significant advancement in automotive repair technology. Its numerous advantages over traditional welding, including enhanced durability, improved aesthetics, corrosion resistance, and weight reduction, make it a compelling choice for both repair shops and vehicle owners. As the automotive industry continues to evolve, adhesive bonding is poised to become the standard for metal car body repairs, offering a reliable, efficient, and high-quality solution for the future of automotive repair.